Carbice® Pad

Tell us what challenges you’re facing, and we’ll work with you to find the best solution.

Carbice® Pad provides better long-term cooling than other TIMs

Electronic devices experience an increasing number of heat management challenges:

- Smaller and more powerful electronics lead to thermal expansion mismatch

- Thermal expansion mismatch causes electronic malfunction and shortens lifespan

- Conventional TIMs fail to dissipate heat over time due to dry-out, pump-out, and formation of air voids

- Electronics de-rate, degrade, and are disposed as e-waste after a short time

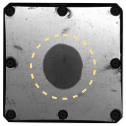

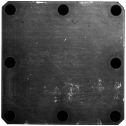

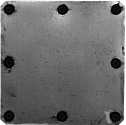

High-Performance Grease C-SAM Analysis

Grease was applied only at the center of the interface (within the dotted circle).

Takeaway:

After only ~50 cycles, the grease has completely dried out.

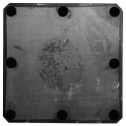

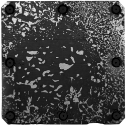

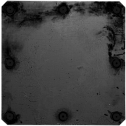

High-Performance PCM C-SAM Analysis

PCM was applied over the entire interface.

Takeaway:

Air voids migrate around interface with PCM.

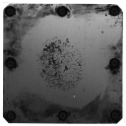

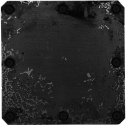

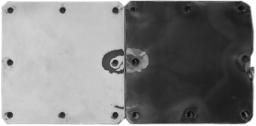

Carbice Pad C-SAM Analysis

Carbice Pad IP150 was applied over the entire interface.

Takeaway:

Carbice Pad cause no interface degradation throughout the 2000 test cycles.

Coupon thermal resistance change due to thermal cycling

Thermal cycling performed from -55 °C to 110 °C for 2000 cycles, according to modified JEDEC standard JESD22-A104F condition L. Thermal conductance measured using ASTM D5470 standard testing method.

Thermal interface quality degrades with increasing cycles for conventional TIMs:

- After 2000 cycles the thermal resistance of grease is 2.6 times that of Carbice Pad

- After 2000 cycles the thermal resistance of PCM is 1.4 times that of Carbice Pad

Using Carbice Pad, customers are able to:

- Remove heat effectively and reliably over time

- Expect less de-rating of electronics over time

- Build higher performance electronics that last longer

- Generate less e-waste and be more sustainable

Carbice® Pad enables better cooling for GPU

The challenge of GPU heat management

GPUs are incorporated by data centers to handle increasingly intensive workloads:

- They are affected by large thermal variances during operation

- Heat buildup reduces GPU’s performance, stability and lifespan

- Reliability of data centers will be compromised

Meet Carbice Pad

Carbice Pad provides high thermal conductivity of a solid TIM and low thermal resistance of a liquid TIM, with reliable long-term performances and high volume manufacturability. For this study, we used IP90 with 2-sided assembly tack.

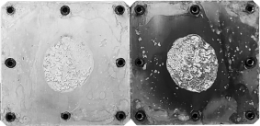

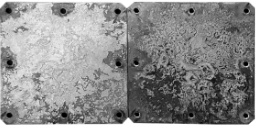

Carbice Pad demonstrated immediate better cooling and long-term gains to GPU performance compared to POR Grease:

- 2℃ cooler upon initial installation

- > 6℃ cooler after extended use

Over time, grease pumps-out and develops dry-cracks, causing its thermal resistance to double after extended use. On the contrary, Carbice Pad wets the interface even better with time and cycling.

Takeaway:

Carbice Pad provides better lifetime cooling performance than grease.

Using Carbice Pad, customers are able to:

- Lower GPU temperature

- Boost GPU performance

- Extend GPU lifespan

- Increase data center reliability