When Carbice engineer, Stefan Anschutz, recently encountered an equipment issue in the Carbice facility, he turned to our own material — Carbice® Pad — to fix the problem. The issue was thermal runaway in a solid-state relay (SSR) for industrial equipment. Using Carbice Pad, Stefan swapped out the product's stock thermal interface material (TIM) for Carbice’s top-performing Carbice Pad.

In this blog, we’ll document how to tackle the failure of a TIM (in this case, thermal grease), thus eliminating the failure mechanism and improving performance. This example shows the power of the Carbice solution: a high performance pad that is reliable, easy to use, and affordable.

Swapping grease for Carbice® Pad is a no-brainer for the SSR application.

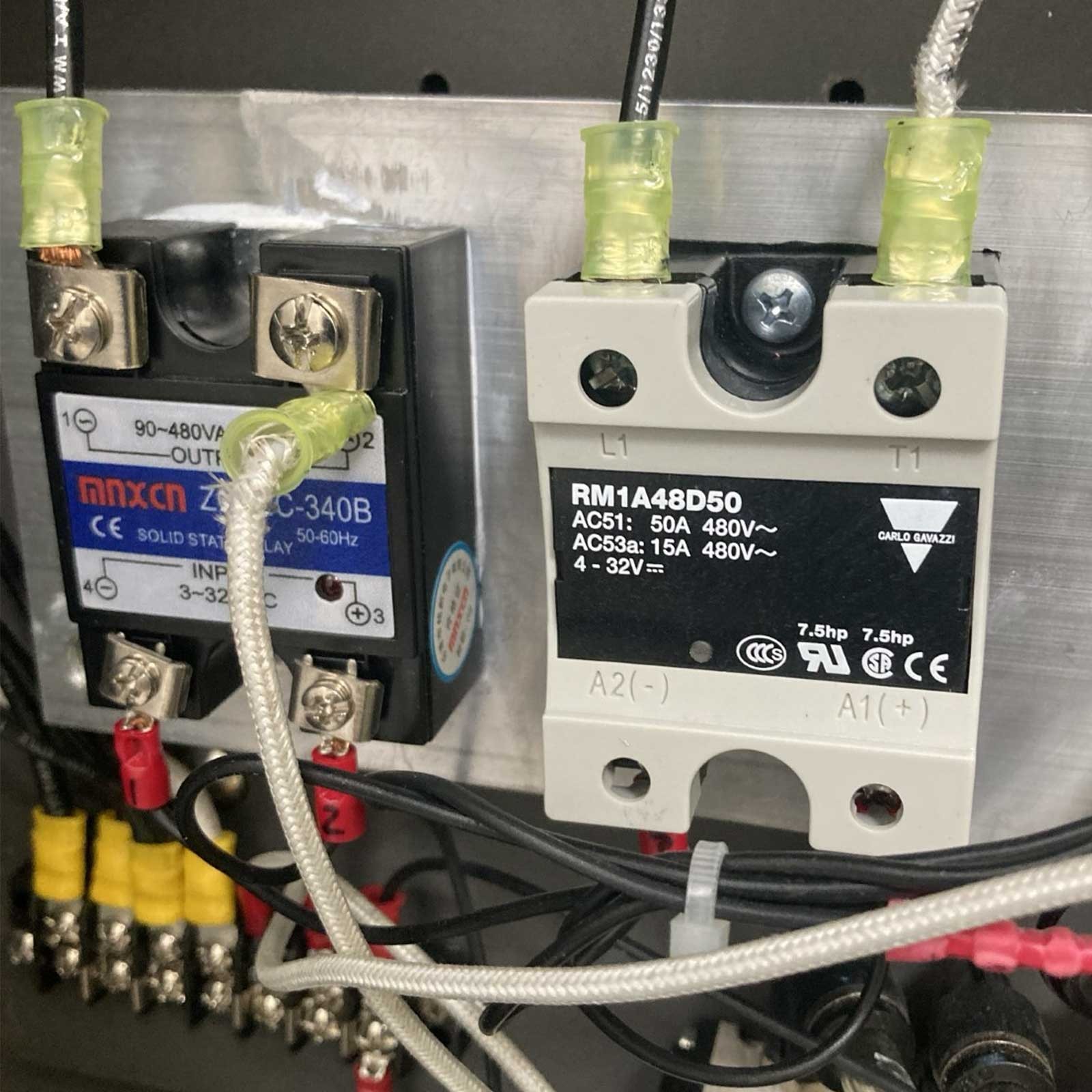

The tool below is a heat press with a higher and lower plate that heats up to ~ 200° C.

Heat press used in Carbice production.

When the SSR failed on the heat press, it shorted out the device — causing a condition called thermal runaway. It shorted, we believe, because the grease failed, leading the device to overheat and creating a scenario where the electrical component was energized when it wasn't supposed to be. The heat press was heating up continuously — “running away,” per Stefan. “It was a runaway heater, and when you have something like that, it normally damages other subcomponents.”

To avoid another short, Stefan used our own Carbice Pad rather than grease. With Carbice Pad, all Stefan had to do was remove the standard TIM, clean the surface a bit and cut the spare materials to size.

As Stefan notes, “I repaired this heat press a few times. Initially it burned out some of the electrical wiring on the bottom plate. I rewired it with high temperature terminals and figured it would be all right — I wasn't sure why it burned out. A couple of hours later, it was plugged in, and the switch was in the off position, effectively ‘de-energized.’ The bottom plate was all the way up to 400° C, as if it was being asked to heat up at full speed, which is strange when the controller isn't on. When I measured voltage across the relay, I found it was delivering full power to the heater circuit. This shows that when this component fails in that way, it would essentially burn through the electrical circuit until there's a component failure — a thermal runaway effect. And that can spiral into all kinds of other problems.”

When this component fails in that way, it would essentially burn through the electrical circuit until there’s a component failure — a thermal runaway effect. And that can spiral into all kinds of other problems.

Stefan Anschutz, Carbice Engineer

Steady State Comparision of Grease v. Carbice. As shown here, operating temperatures are equivalent. Carbice is performing as well as grease — without the concern of failure.

It was ultimately a clean plug and play solution that fixed the issue. Carbice Pad has many advantages over other traditional thermal interface materials. It’s naturally tacky (unlike grease) and not slippery (unlike graphite), allowing for easy installation. Every millimeter of the surface is covered by thermal interface without gaps.

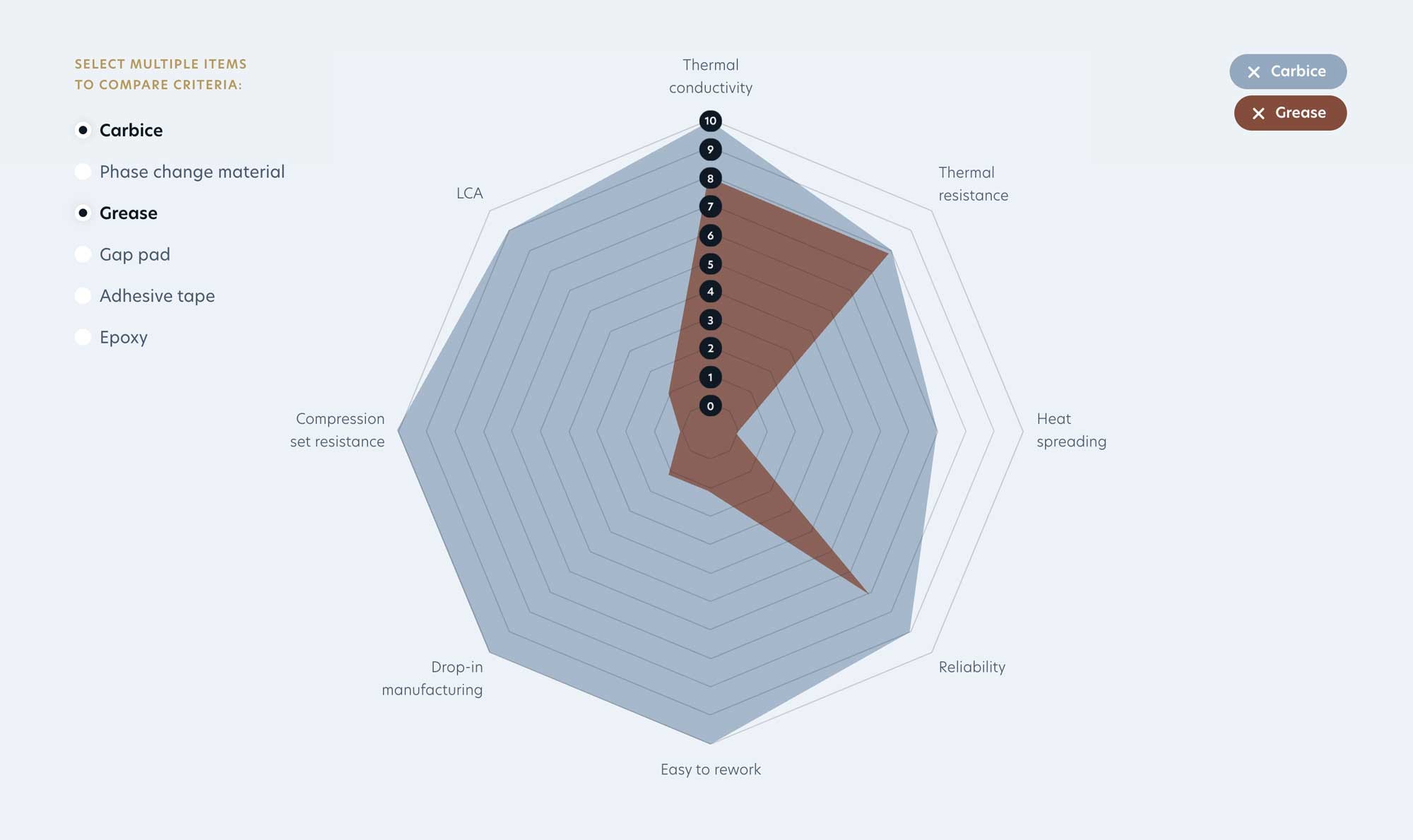

Carbice has proven advantages across all of the important criteria—making it the ideal thermal management solution for any project. Compare material properties here.

Carbice Pad | Application and Removal from Carbice Corporation on Vimeo.

“In a pinch, our Carbice® Pad material is easy to work with when other materials fail,” says Stefan. “I think it's an interesting application for our material because a lot of different tools use SSRs to control high temperature circuits and if you have one of those subcomponents fail — if it's in a critical spot — it could cause a destructive effect. We should always be looking for a better solution. I would suggest that every equipment or facility engineer keep Carbice Pad handy for quick resolution of these types of problems.”

In a pinch, our Carbice Pad material is easy to work with when other materials fail... I would suggest that every equipment or facility engineer keep Carbice Pad handy for quick resolution of these types of problems.

Stefan Anschutz, Carbice Engineer

Ultimately, Carbice Pad is more reliable and also uniquely predictable, with modeling capabilities that are impossible with grease and other traditional TIMs.

- Learn more about Carbice® Pad here.

- Learn more about modeling with Carbice SIM here.

- See the post “Protect your high-performance GPU or CPU from overheating.”

For Reference:

Thermal Runaway:

In electrical engineering, thermal runaway is typically associated with increased current flow and power dissipation. Thermal runaway occurs in situations where an increase in temperature changes the conditions in a way that causes a further increase in temperature, often leading to a destructive result as Stefan observed in this experience.

Solid-state relays (SSRs)

SSRs are used to control electrical loads. Their primary function is to activate a single output load when energized. SSRs are efficient and effective and can allow for extremely large loads to operate with very precise control voltages. For large load devices such as heaters and motors, SSRs can be a major advantage over traditional mechanical relays. SSRs are the preferred option for very precise high-speed switching given their efficiency and long operational life.

There are a vast number of applications for SSRs with the majority in industrial manufacturing, with hundreds of possible uses. Most can be categorized into the following type of load applications: heating elements, motor control, lighting and power devices. While using SSRs in high-temperature circuits can help to prevent thermal runaway and the resulting effects of component failures — but the TIM in place needs to hold up in the application.