Don’t let cheap paste ruin your processor. Expand your device’s performance with carbon nanotube-based pads from Carbice — an affordable, long-lasting solution for hotspot issues.

—

In the world of electronics and high-performance computing, managing heat efficiently is crucial. The thermal interface material (TIM) plays a pivotal role in ensuring that heat generated by components is effectively transferred to heat sinks or other cooling solutions.

While traditional paste-like TIMs have been the norm for years, their quality, and the consistency of their installation, can vary greatly resulting in poorly performing systems. Moreover, when manufacturers use cheap or low-quality paste-like solutions, the results can be catastrophic — as is the case for the recent Nvidia GeForce RTX 40 Series GPUs (Nvidia GPU partners reportedly cheap out on thermal paste, causing 100C hotspot temperatures — cheap paste allegedly degrades in a few months | Tom's Hardware (tomshardware.com)).

Fortunately, innovative materials such as aligned graphite/graphene pads, Carbice Pad (novel substrate-supported aligned carbon nanotubes), and phase change materials (PCM) are changing the landscape, enabling high performance. We’ll explore why these materials could be the better choice compared to conventional paste-like TIMs that tend to degrade over time, and we’ll cover aligned carbon nanotube-based materials specifically, which promise durability and superior performance and have already been battle-tested in satellites orbiting earth.

Relative to other high-end pads (aligned graphite, graphene, or carbon fibers), aligned carbon nanotube (CNT) pads from Carbice are thinner, more robust, and approximately a third of the cost due to simple growth strategies and a unique structure. Carbon nanotubes are quickly grown using waste gas and are permanently bonded to a strong, inner aluminum foil core that holds the material together — alleviating concerns over tearing and folding and/or sliding around during installation.

Relative to PCM, the Carbice Pad is easier to handle and install, staying intact when the protective liner is removed. It will not pump out or flow out at high temperatures and is also less expensive than standard PCM.

With Carbice Pad, customers can achieve the best temperatures that high-end pads can offer, but at a much more affordable price and a better user experience.

Easy handling and installation with Carbice Pad

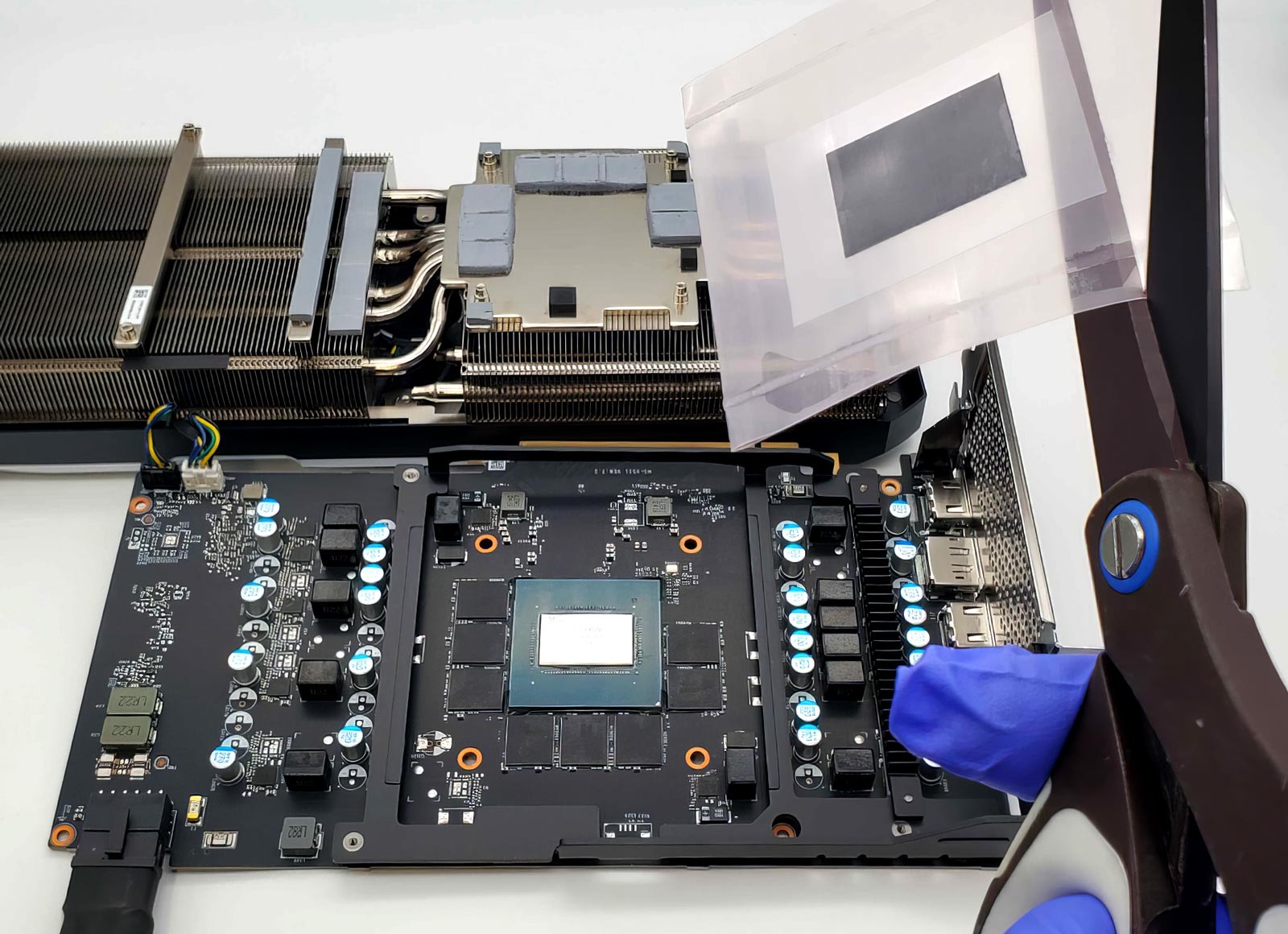

Image 1. Carbice Pad being cut from the packaging in preparation for installation on the RTX 4080 Super.

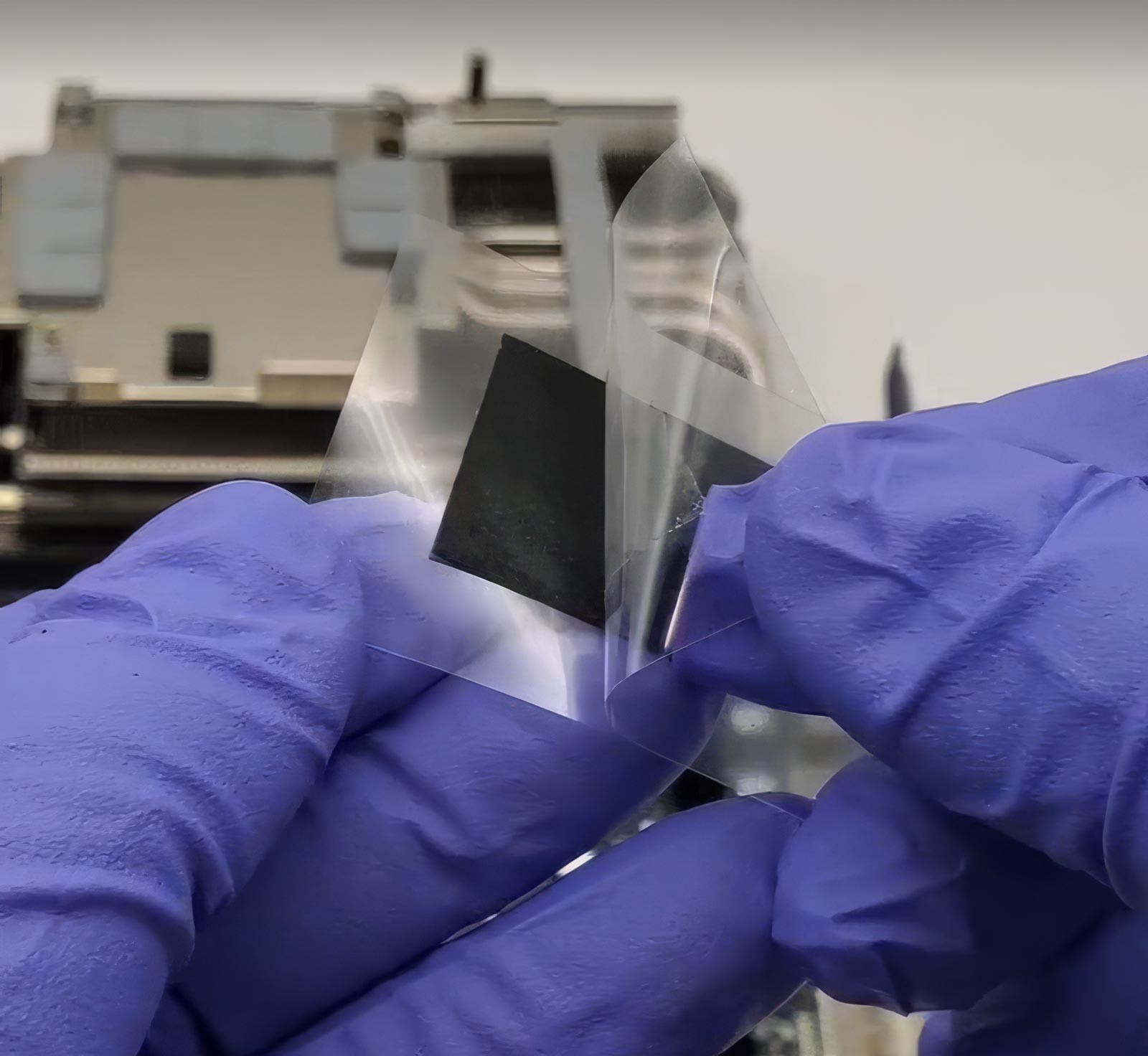

Image 2. Removing the plastic liner from one side of the Carbice Pad.

Understanding Thermal Interface Materials

Thermal Interface Materials are used to fill the microscopic gaps between heat-generating components and their heat sinks. The primary function of a TIM is to reduce thermal resistance, ensuring efficient heat transfer. Traditionally, TIMs come in various forms, including thermal pastes, pads, and PCM.

Carbice Pad Carbon Nanotube-Based Thermal Interface Materials

1. Exceptional Thermal Conductivity:

Carbon nanotubes are renowned for their extraordinary thermal conductivity, which can be up to 10 times higher than traditional metals. This property enables CNT-based TIMs to transfer heat more efficiently, reducing the risk of overheating and enhancing the overall performance of electronic devices.

2. Durability and Longevity:

One of the most compelling advantages of CNT-based TIMs is their durability. Unlike paste-like TIMs, which can dry out, pump out, or degrade over time due to thermal cycling or mechanical stress, CNT-based TIMs maintain their thermal conductivity over long periods. This is because carbon nanotubes have a highly stable structure that resists degradation, ensuring consistent performance throughout the product's lifespan.

3. Mechanical Strength and Elasticity:

Carbon nanotubes also impart exceptional mechanical strength to TIMs. They are strong and elastic (spring-like), meaning that CNT-based materials can withstand physical stresses and vibrations better than paste-like TIMs, which can lead to cracks or displacements over time.

4. Thermal Stability:

CNT-based TIMs exhibit superior thermal stability, maintaining their performance across a wide range of temperatures. This stability makes them ideal for high-performance applications where temperature fluctuations are common.

5. Low Thermal Resistance:

CNT-based materials can achieve low thermal resistance with minimal thickness. This allows for more compact designs without compromising thermal management efficiency.

Paste-Like Thermal Interface Materials

1. Initial Performance:

Traditional paste-like TIMs offer good thermal conductivity when first applied, making them effective for new devices.

2. Degradation Over Time:

One of the significant drawbacks of paste-like TIMs is their tendency to degrade over time. They can dry out, pump out, or become less effective due to thermal cycling. This degradation results in increased thermal resistance, which can lead to overheating and reduced performance of electronic components. This problem is becoming more pronounced as the industry moves toward large surface area devices that are warped and experience dynamic warping over the operating lifetime.

3. Application Challenges:

Paste-like TIMs require careful application to avoid air bubbles or uneven distribution, which can negatively impact their thermal performance. Additionally, over time, the material can shift or settle, affecting its effectiveness.

4. Periodic Maintenance:

Due to their tendency to degrade, paste-like TIMs may require periodic reapplication or maintenance. This can be inconvenient and costly, especially in high-density or high-performance applications where frequent servicing is impractical.

Thermal Performance Comparison

The thermal performance of a Nvidia GeForce RTX 4080 Super GPU was measured to assess both long- and short-term performance of the thermal interface. As shown in the image below, we installed a Carbice Pad on the RTX 4080 Super device and ran thermal benchmarking to compare the hot spot temperature of the OEM paste to the Carbice Pad after initial installation and after cycling to simulate 6 months of use. Furmark is used for benchmark testing the RTX GPU. Furmark is a stress test that is able to consistently and steadily pull and use the max power from the GPU. To ensure steady state, Furmark is run for 15 minutes (with 100% fan power) before 3 minutes of on and off cycling begins. The 100% fan power increases the significance of the TIM in the thermal stack and enables more clarity when comparing TIM performance.

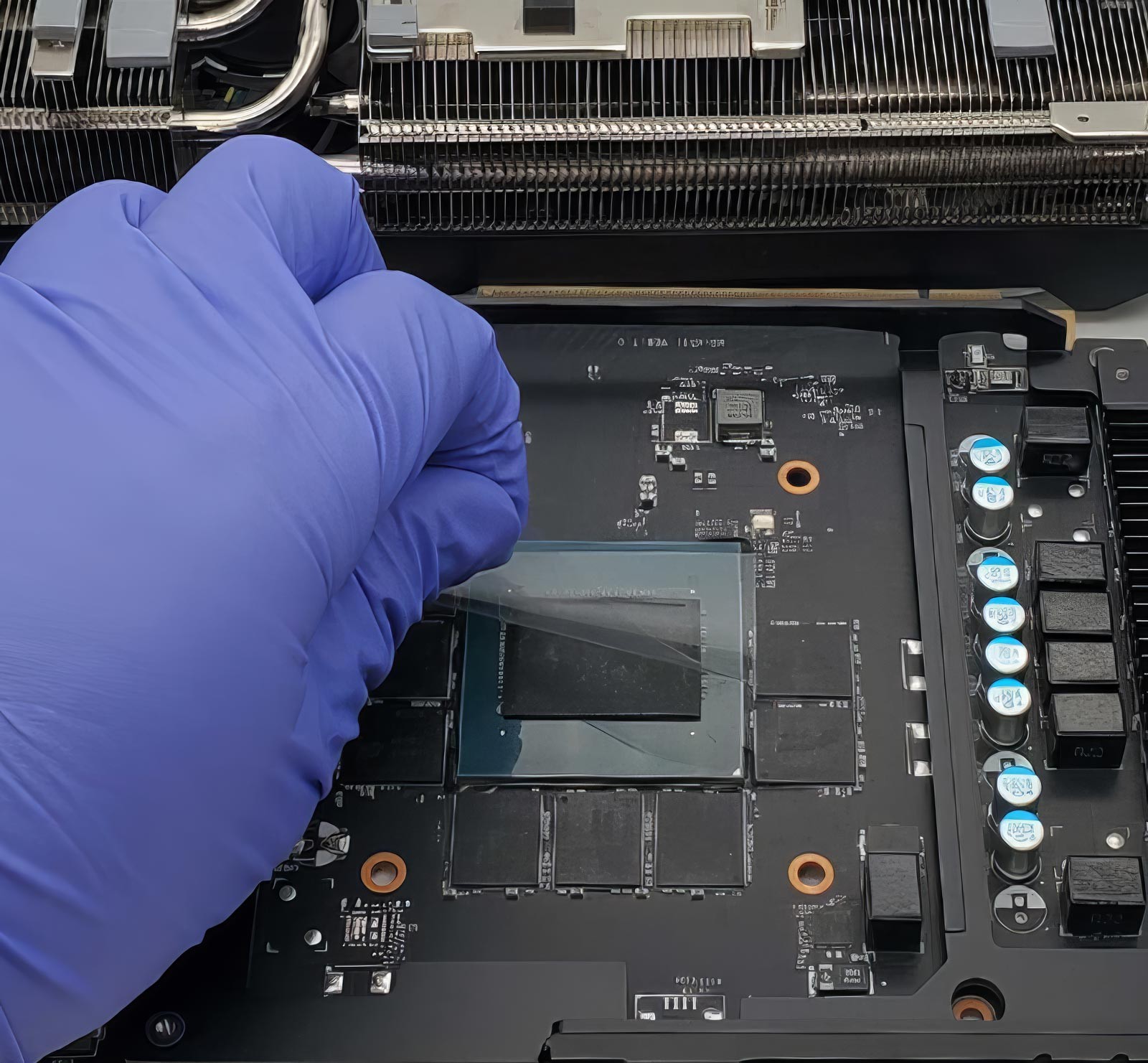

Image 3. Pressing the Carbice Pad to the die and then removing the top plastic liner.

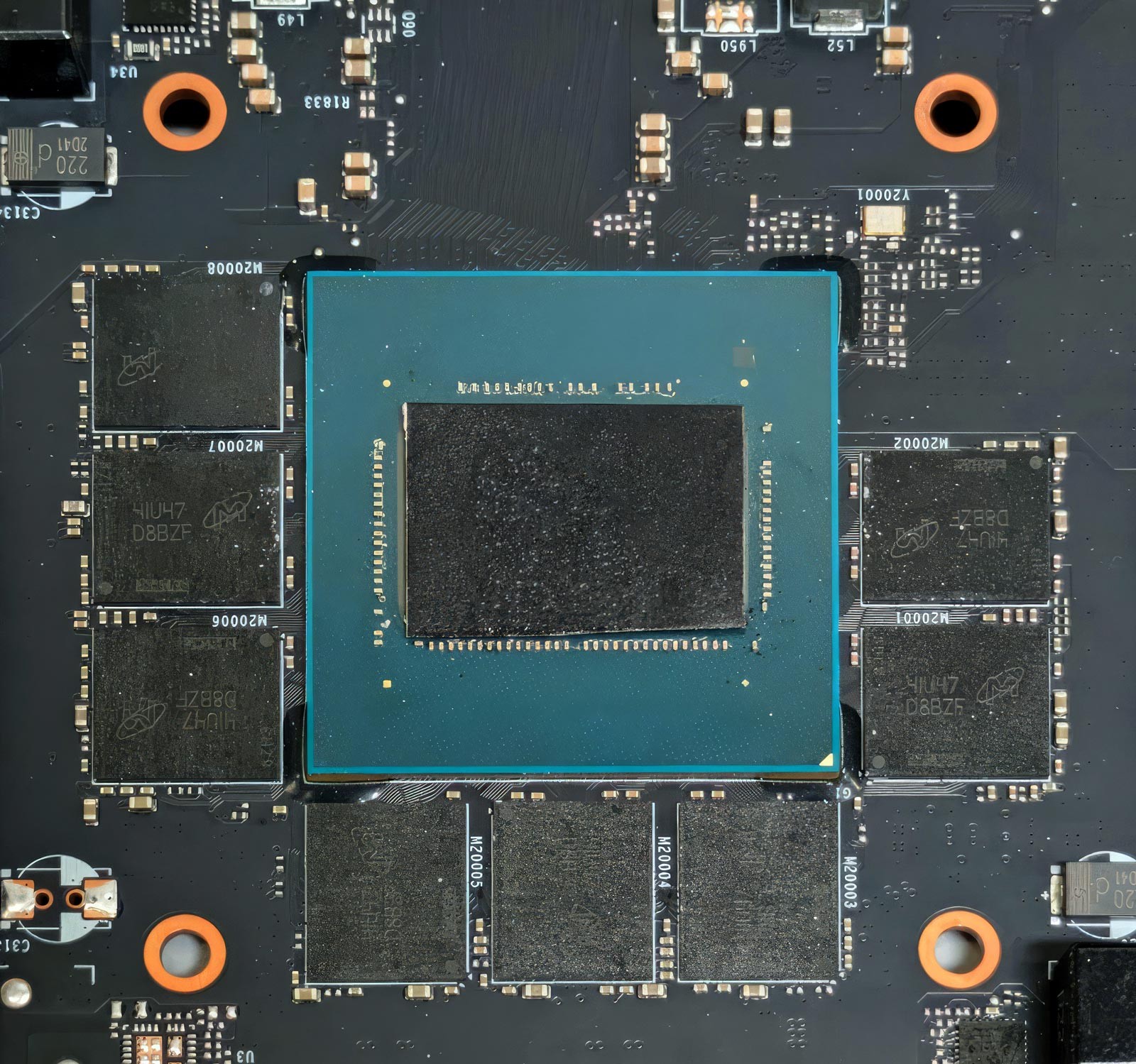

Image 4. The Carbice Pad installed on the RTX 4080 Super.

As shown in Figure 1, Carbice Pad materials actually improve with thermal cycling and show no degradation after 6 months of cycling — whereas the OEM grease can have hot spot temperatures above 100º C after only 6 months of use despite the initial good performance. Carbice will continually update our customers with thermal performance as a function of time to demonstrate the durability of our materials.

Figure 1. Initially, the OEM grease performs quite well and is slightly better than the Carbice Pad. However, after only 6 months of cycling, Carbice Pad outperforms the OEM grease by more than 30º C and is well below the required operating temperature for optimum performance.

Reliability and higher performance without the high cost

The following costs are specifically for the Nvidia GeForce RTX 40 Series GPU:

Figure 2. Cost comparison of TIM pricing; Amazon.com as of August 2024.

Conclusion

While traditional paste-like TIMs have been the norm for years, their quality, and the consistency of their installation, can vary greatly resulting in poorly performing systems. This issue highlights the need for more advanced solutions.

Nvidia recently experienced this firsthand when a vendor used low quality grease on their GeForce RTX 40 Series GPUs. The devices began to reach hotspot temperatures above 100ºC within a few months of operation due to the grease pumping out, causing fan speeds to spike to nearly 100%.

With their superior thermal conductivity, durability, and stability, Carbice Pads offer a compelling alternative, addressing many of the shortcomings of traditional paste-like TIMs and providing a more affordable, easy to implement, and reliable solution for efficient thermal management.

Moreover, other state of the art solutions such as PCM and aligned graphite/graphene/carbon fiber are expensive, difficult to handle, and have the tendency to tear or pump out/dry out during operation.

As technology continues to advance and electronic devices become more powerful, the demand for high-performance thermal management solutions will only grow. Carbon nanotube-based TIMs represent a significant leap forward, promising not just improved thermal performance but also increased longevity and reliability, making them a smart choice for today’s applications.