As we continue engaging with our customers and partners, it’s clear that carbon-based TIMs are gaining traction as a promising solution to the growing thermal challenges driven by rapid advances in AI and power technologies. Yet, one thing we’ve noticed is that there’s still a lot of uncertainty around the differences between the various carbon-based products on the market. That’s why we wanted to take a moment to clarify what truly sets Carbice apart from other carbon-based materials like graphite and vertically aligned graphite.

Carbice is a unique TIM in that it combines many of the benefits of existing carbon-based TIMs with distinct advantages associated with its nano-engineered mechanical structure and metal core. Below we’ll compare Carbice with graphite heat spreaders and vertically aligned graphite TIMs in 7 different categories. We hope to show you that Carbice Pad is a distinct product to existing graphite-based TIMs with superior benefits in critical applications like data center GPUs and CPUs.

1. Thermal Conductivity

Carbon is capable of exhibiting very high thermal conductivity, but this thermal conductivity can vary significantly depending on the direction of travel within a material. This is known as anisotropy. For example, since graphite is composed of many, many layers of graphene (single molecule thick sheets of covalently bonded carbon) the thermal conductivity within the xy plane (within a sheet of graphene) is very high, but the thermal conductivity in the z direction (in between the individual sheets of graphene within the graphite) is low, limiting the effectiveness of graphite as a TIM. Vertically aligned graphite TIMs have attempted to solve this problem by aligning many, many sheets of graphene vertically so that they exhibit high thermal conductivity in the z direction (through-plane) but low thermal conductivity in the xy plane (in-plane).

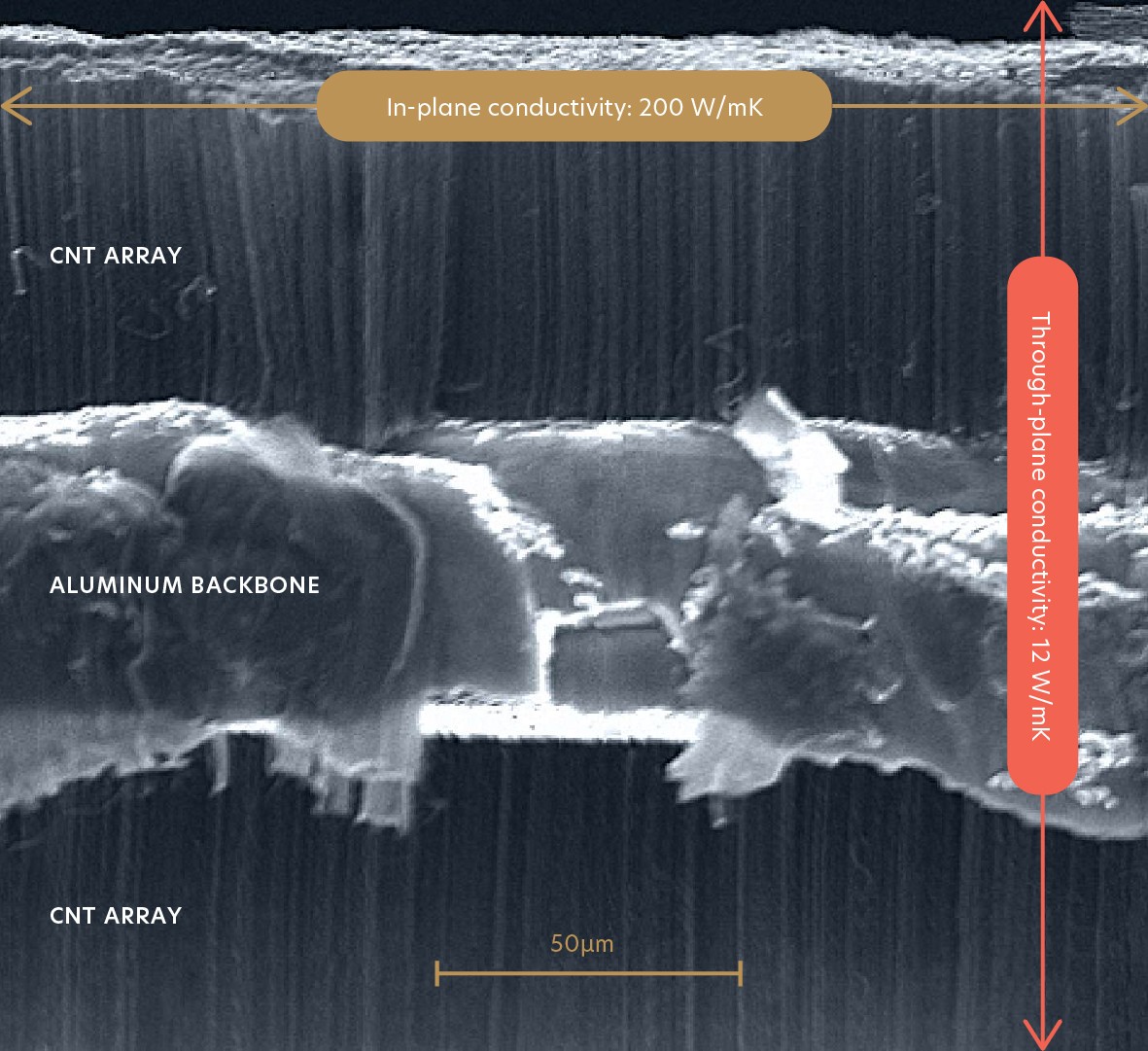

Carbice Pads overcome the need for this tradeoff in through-plane and in-plane thermal conductivity with its unique architecture. By growing vertically aligned carbon nanotubes directly on a metal foil core, Carbice Pad exhibits high thermal conductivity through-plane through the carbon nanotubes, 12 W/mK, and very high thermal conductivity in-plane within the metal core, 200 W/mK.

Scanning Electron Microscope (SEM) imaging of the Carbice Pad solution.

With Carbice Pad there is no need to choose between optimizing thermal conductivity in-plane and through-plane, you can have both! This is particularly useful when trying to deal with hotspots on active devices as the combination of heat spreading in-plane and high thermal conductivity through-plane can deal with large heat fluxes in relatively small areas.

2. Mechanics

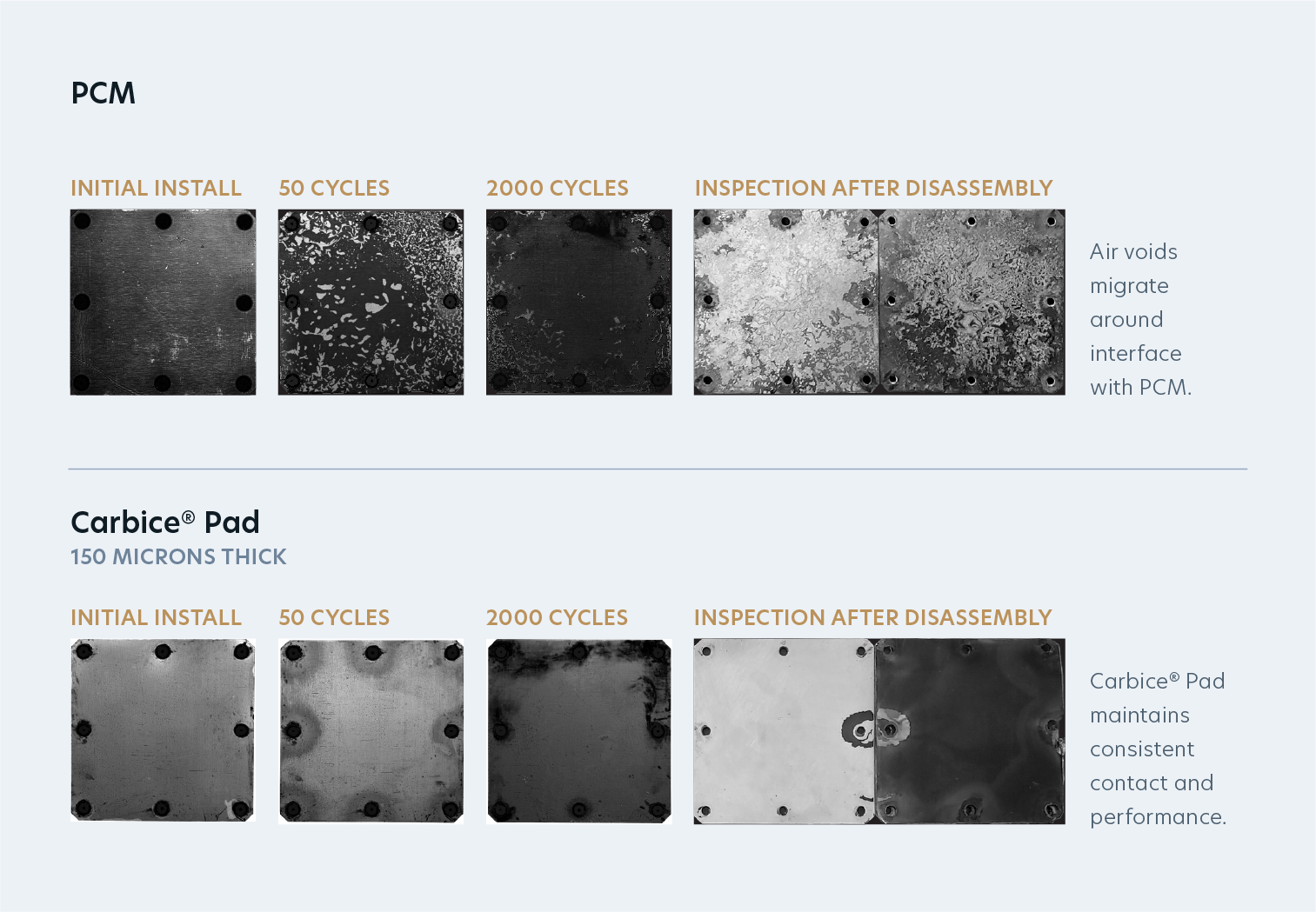

The two most dominant failure mechanisms in thermal interface materials are shear delamination and compression set. Shear delamination is the loss of adhesion or separation between interfaces due to shear forces, i.e. lateral forces in-plane like a heat sink and chip sliding against one another laterally. Compression set is the permanent deformation or loss of thickness of a material when it is compressed. A TIM experiences both lateral shear and compressive forces during thermal cycling caused by variations in device workload and differences in the coefficients of thermal expansion of different materials in the device, TIM, and heat sink or cold plate. It is thus essential that a reliable TIM can resist both shear delamination and compression set in order to maintain good thermal contact during extended use. Liquid TIMs such as phase change materials can experience pump out due to shear delamination, which is why the performance of phase change materials degrade over time. Graphite films and vertically aligned graphite are both highly compressible, but they are NOT elastic, meaning that once they are compressed they do not bounce back to their original thickness and often crack and flake. This means that over time they are compressed during thermal cycling and begin to lose thermal contact, degrading their performance.

It is thus essential that a reliable TIM can resist both shear delamination and compression set in order to maintain good thermal contact during extended use.

Aligned graphite TIM embossed with stamp (shown on the right) demonstrating lack of elasticity, leading to compression set.

Due to proprietary processing that modifies the nanotubes’ surface, Carbice carbon nanotubes exhibit unique mechanical properties in that they are extremely elastic, like a spring, and therefore able to absorb tremendous stress without breaking or permanently deforming.

Instron testing demonstrating elasticity of Carbice material.

Carbice Pad can therefore be thought of as consisting of billions of individual nano springs that are each capable of independently absorbing stress so that Carbice Pad does not experience shear delamination or compression set and maintains intimate thermal contact during long term use.

3. Durability

The elasticity of Carbice Pad’s carbon nanotubes help it maintain efficacy during long term use. Similarly, its robust metal core makes it extremely durable. The metal core of Carbice Pad is >10 times as tear resistant as graphite, making graphite TIMs much more likely to tear or degrade during assembly and use. Likewise, Carbice Pad does not use any structural adhesive like vertically aligned graphite TIMs do, so unlike vertically aligned graphite TIMs, there are no structural organic compounds in Carbice Pad that will degrade over time exposed to heat.

The metal core of Carbice Pad is >10 times as tear resistant as graphite, making graphite TIMs much more likely to tear or degrade during assembly and use.

Third party test by NREL demonstrates Carbice’s ability to withstand shear delamination during long-term cycling compared to phase-change material (PCM).

4. Ease of Use

Because graphite is composed of many, many sheets of graphene that are weakly bonded to each other, the sheets of graphene can easily slide past each other. This is why graphite is such an excellent lubricant, because it is slippery at the molecular level! Unfortunately, this also makes graphite TIMs difficult to work with as they slide and slip out of place during assembly, making installation more difficult and prone to human error. Carbice Pad has built-in assembly tack due to our proprietary nanotube surface coating technology, making it as easy to install as peel-and-stick!

Image depicting simple peel and stick assembly process for the Carbice Pad solution.

5. Supply Chain

Approximately 80% of the world’s graphite is produced in China. Due to the importance of graphite for battery manufacturing, China has imposed export restrictions on graphite that constrict an already fragile graphite supply chain. Recent global tariff policy changes also dramatically complicate the availability of graphite and graphite-based materials outside of China. In contrast Carbice is made in the United States from commodity materials available from many different vendors all over the world. Carbice Pad manufacturing sites could additionally be sited around the world as needed as we do not need access to any special resources or chemicals.

6. Environmental

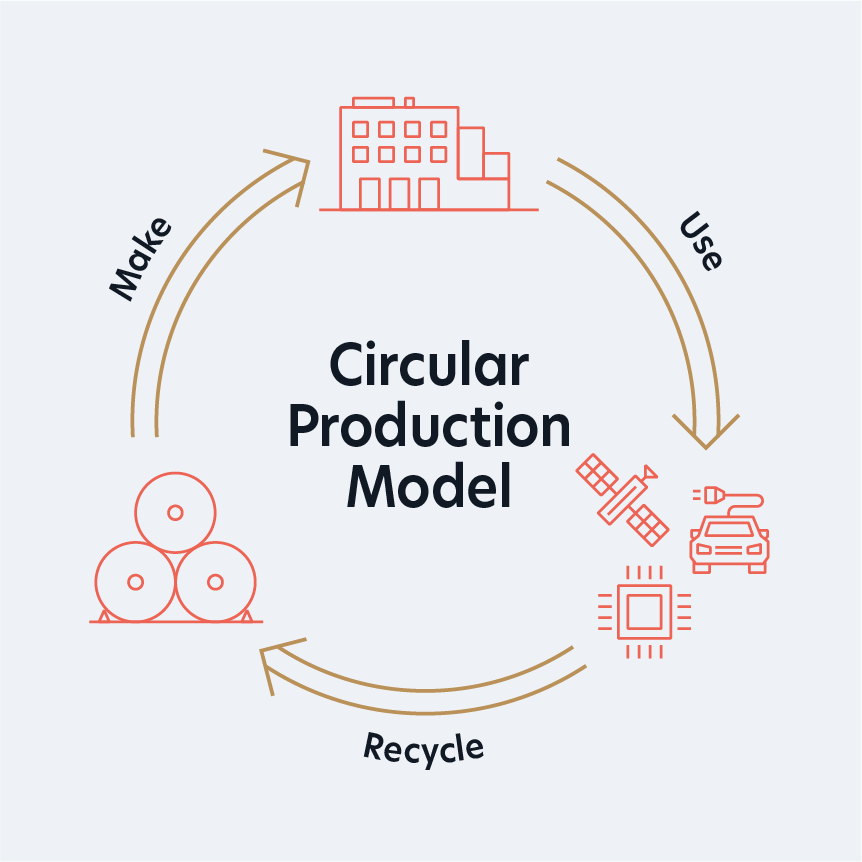

Beyond performance, sustainability has become an equally important factor in TIM selection—especially for companies with aggressive net-zero or Scope 3 emission reduction goals that account for the environmental impact of their entire supply chain. Graphite can either be mined from natural deposits or synthetically made. When it is mined 5-10 tons of earth must be moved and processed to produce a single ton of graphite. Making graphite synthetically requires heating oil and/or coal by-products >3000 °C for long periods of time. This requires very large amount of energy, which because graphite production often occurs in China often comes from coal-fired power plants. For these reasons both natural and synthetic graphite have high carbon footprints of approximately 6 kg CO2 equivalent/kg natural graphite and 14 kg CO2 equivalent/kg synthetic graphite. However, a recent white paper from a respected life cycle analysis consulting firm estimated these values may actually underestimate the carbon footprint of graphite by as much as 1000%! Clearly the production of graphite is a large source of global warming gases. Carbice Pad is in contrast manufactured using recycled aluminum and waste carbon gases in a low-temperature, energy efficient circular production process—helping our customers meet their performance and sustainability objectives without compromise.

When it is mined 5-10 tons of earth must be moved and processed to produce a single ton of graphite. Making graphite synthetically requires heating oil and/or coal by-products >3000 °C for long periods of time.

Carbice Circular Production Model

7. Economics

Because of Carbice’s innovative and efficient manufacturing process the intrinsic economics of Carbice’s TIMs is also more favorable than graphite-based TIMs. This means that not only is Carbice more durable and sustainable than graphite-based TIMs, but also less expensive. For example, the Carbice® Ice Pad is currently being sold as an option for CyberPowerPC’s made-to-order gaming desktop computers. Carbice Ice Pad is being offered at nearly 60% less than the cost of a competing vertically aligned graphite TIM!

In Conclusion

Carbice Pad stands apart by combining exceptional 3D heat transport with unmatched mechanical durability—delivering consistent performance where other TIMs degrade over time. Its nano-engineered structure and circular manufacturing process not only solve today’s toughest thermal challenges but also align with the sustainability goals of the world’s most forward-thinking companies.

If you’re looking to enhance thermal reliability, simplify assembly, and strengthen your supply chain resilience, reach out to learn how Carbice can help you with higher performance, longer lasting, and more sustainable systems.