If you are paying attention to the thermal interface material space, at this point you’ve probably heard of liquid metal. But what is a liquid metal TIM? Liquid metal TIMs are metal alloys made from gallium, indium, and other metal alloying elements. But aren’t metals solid? They usually are! But gallium is a metal with a very low melting temperature of only ~30°C, only about ~5°C above room temperature. Other elements can be added to gallium to further lower its melting temperature, making it liquid at ~room temperature. Metals are very good thermal conductors, so a liquid capable of perfectly filling an interface to maintain intimate contact between both a device and cooling component that is also a very good thermal conductor sounds like a great TIM.

But there are a few big problems with using liquid metal as a TIM. First, it’s a liquid. Yes, this is a strength as it allows for dynamic, intimate contact with surfaces, but it also means that it flows, which means it can leak! Special dams have to be built around the thermal interface in order to contain the liquid and ensure it doesn’t spill or leak out. But of course, it often does spill or leak out! Which leads us to problem number 2. In addition to being thermally conductive, liquid metal is electrically conductive. This means that if it does leak out, it can short electrical components and therefore functionally destroy electrical devices. Linus Sebastien of YouTube’s Linus Tech Tips fame learned this the hard way. In a recent video on his Linus Tech Tips channel, he painstakingly details his frustration with trying to fix a laptop manufactured with a liquid metal TIM.

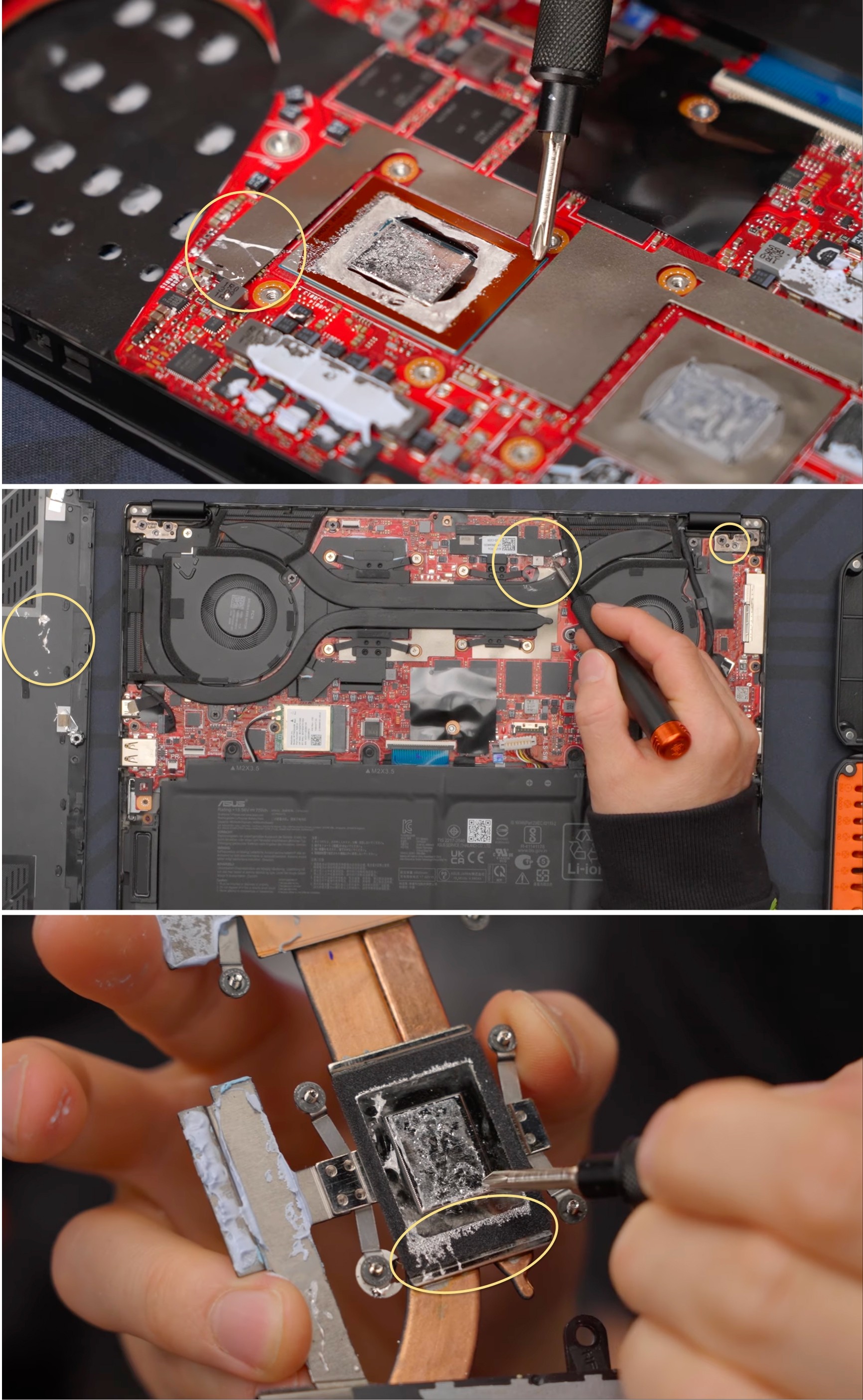

Daily wear and tear apparently broke the dam meant to contain the liquid metal, spilling this electrically conductive liquid all over his laptop’s internal components! This led to a short that prevented the laptop from booting. Despite his best efforts, Linus was ultimately not able to salvage his laptop, even after disassembling it, removing the spilled liquid metal, resoldering components ruined by the spilled liquid metal, and then reassembling his laptop.

Screenshots above from Linus Tech Tips: Disassembled laptop showing liquid metal TIM leakage (yellow circles) from failed containment dam.

The Carbice Solution

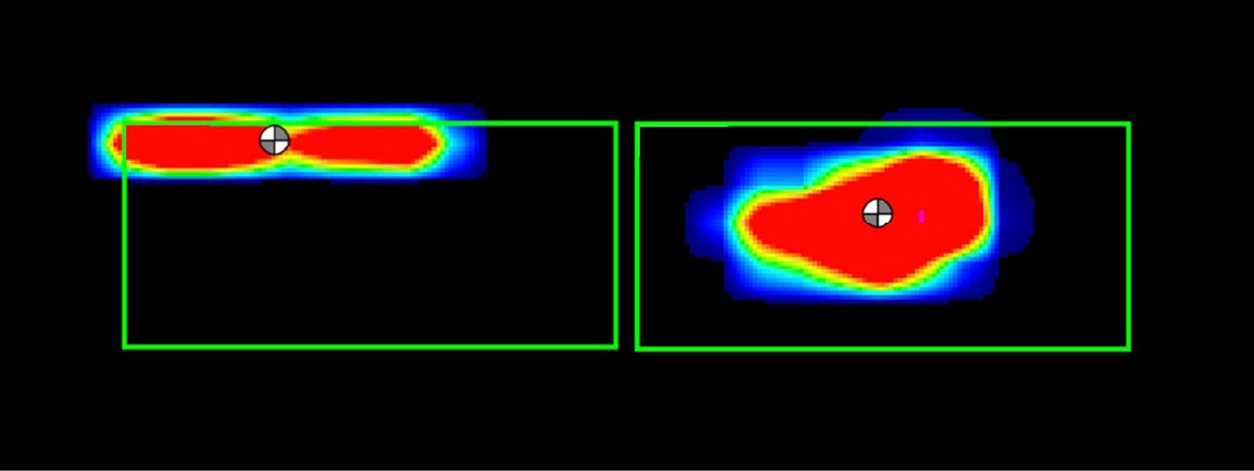

The good news is that Carbice can provide a solution for laptops that outperforms liquid metal TIMs with none of the leakage and shorting risks associated with liquid metal. Carbice recently partnered with a leading global laptop OEM to co-develop a next-generation thermal architecture. The Carbice team began by precisely measuring alignment, contact regions, and mechanical behaviors between the heatsink and processor. Variations in material stiffness, bolt pattern, and torque caused uneven pressure across the die. By redesigning the bolting pattern and optimizing torque, the teams achieved uniform contact—demonstrating that a solid TIM like Carbice, combined with optimized mechanical design, can outperform liquid TIMs that mask mechanical issues but create manufacturability and long-term reliability issues.

With refined fasteners and optimized pressure distribution across the de-lidded processor, the new design fully leveraged Carbice’s vertically aligned carbon nanotube (CNT) thermal interface—delivering efficient, reliable heat transfer without the compromises of liquid metal and setting the foundation for future laptop designs.

Example of pressure distribution map of chip before and after optimizing mechanical design with Carbice engineering team.

The Carbice Pad delivers exceptional thermal performance — combining high thermal conductivity with low thermal resistance in a durable, solid-state form. It achieves liquid-metal level performance without mess, risk, or degradation when combined with optimized mechanical design. By optimizing mechanical design with Carbice CNT technology, it outperforms phase-change materials and liquid metals in both performance and reliability. Additionally, the Carbice Pad enhances serviceability and ease of assembly, and it’s recyclable!

Cinebench 24 scores of laptop with different thermal cooling solutions: Carbice + mechanical design optimization, phase change material (PCM) + mechanical design optimization, and liquid metal with OEM mechanical design.

Carbice is more than a TIM manufacturer, we’re thermal engineering and mechanical design experts that can combine our expertise with our CNT-based TIM to help you solve complex thermal design challenges. In the example described here, the OEM was able to exceed its thermal and manufacturing goals by working with Carbice to co-optimize material performance and system mechanics — achieving higher reliability with lower cost and complexity.